Endlessly Adaptable

Put Our Foundries to the Test

Have large or unique production needs? Challenge accepted.

With two state-of-the-art facilities at our disposal and dozens of machining and finishing partners located throughout the country, we’re able to tackle any project big or small.

Contact our team to get started.

Case Studies

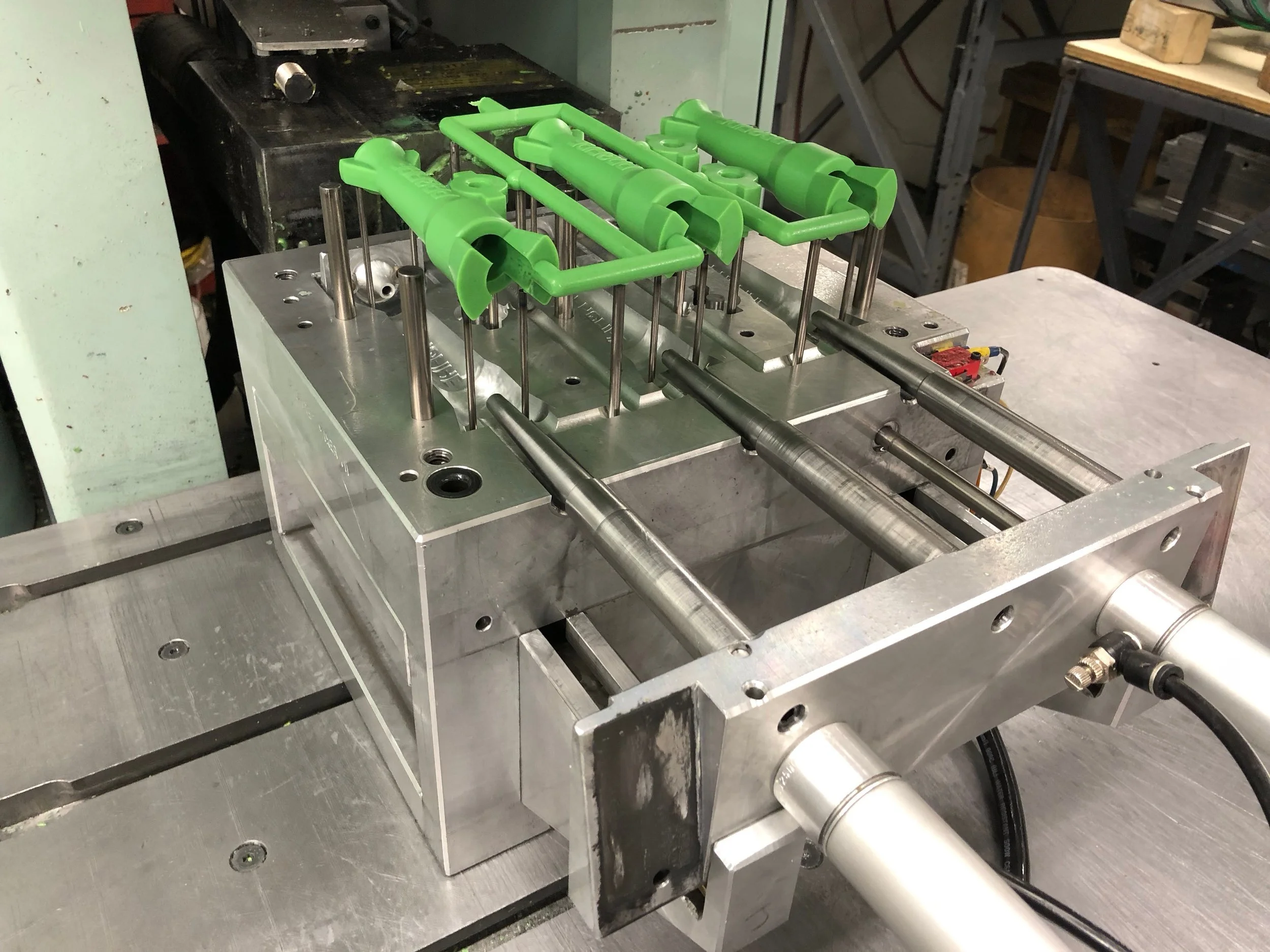

Browse a few quick examples of how we’ve updated our facilities and equipment to meet the needs of our customers.

Conveyor System - Utah Facility

Automation + Industry Experts

A Hands-On Approach to Automation

Automation (like our robotics) allows us to produce incredibly consistent, high-precision castings around the clock. When coupled with our engineers and production staff, we can seek out optimizations in each step of production, allowing for greater control, speed, and cost-saving measures for you.

With our hands-on approach to automation, you can count on custom-tailored production for each of your project’s nuances and perfectly produced parts every time.

Case Study #2

Custom Finishing Robotics

See Us in Action

Schedule a Free Foundry Tour

Want to see what we’re capable of first-hand? Schedule a free in-person tour of an IPC foundry! Get your questions answered, learn about our process, and see why IPC is the perfect fit for your investment casting needs.

Tours take about 20 minutes; book yours today!